There is no such thing as one stainless steel

In the blast furnace, iron ore is processed into pig iron, at this stage it is very hard but still brittle. Various processes are used to eliminate carbon and some accompanying substances.

Stainless steel is produced by adding chromium and other alloying metals to the molten steel. The chromium content primarily gives stainless steel its corrosion resistance. This creates a natural and continuous chromium oxide layer on the surface. This oxide forms a passive layer on the surface of the stainless steel, which not only protects it permanently against all types of corrosion. It is also regenerative, i.e. it heals itself as soon as it comes into contact with water or air.

The alloying metals and their composition and proportions vary depending on the application for which the stainless steel is produced (architecture, medicine, household, industry, shipping...). These alloying metals include chromium, molybdenum, nickel and titanium.

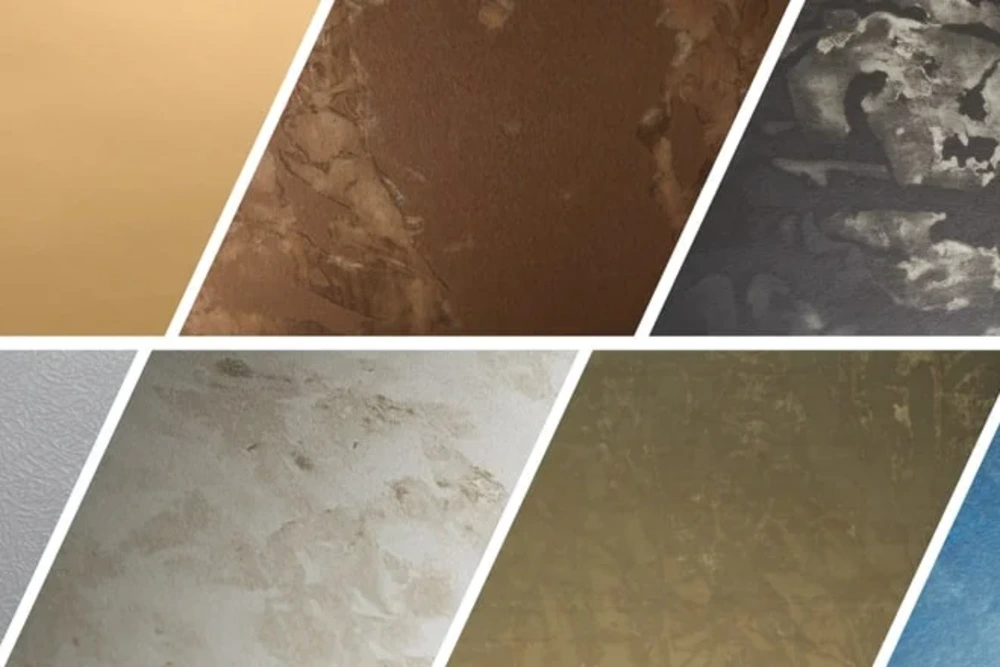

In the production of strips and sheets, there are hot-rolling and cold-rolling processes. ROOFINOX HFX stainless is cold-rolled last, which allows us to produce specifically designed surfaces. This results in different functional and visual qualities that characterise the diversity of the ROOFINOX product range.

ROOFINOX diversity - Like no other.