Why does patinating stainless steel only have ONE permissible place of use?

Did you know that patinated stainless steel is only suitable for roofs?

Find out why patinated stainless steel should not be used for skirting boards, roof overhangs or facades.

ROOFINOX is the inventor of HFX stainless. We are an Austrian manufacturer and the only complete supplier of roof and facade systems. Like no other.

Why was patinated stainless steel developed?

Patinated stainless steel was introduced around 40 years ago. The tin-plated surface, with its natural ageing or patination, was introduced as an alternative to zinc and lead because the possibilities of carefree and glare-free HFX stainless did not yet exist.

Low-alloy stainless steel (ferritic) with patina is still used - but often because knowledge about the better, care-free alternative is not known!

It is also often not known that patinated stainless steel is only permitted for the roof and for bonding sheets, as the patina is very sensitive and virtually impossible to clean.

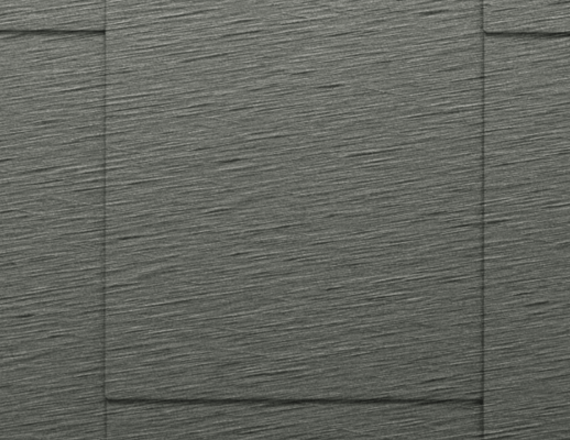

"Proper HFX stainless", i.e. untinned and yet 4-fold matte stainless steel (austenitic) in the alloys 1.4301 (V2A) and 1.4404 (V4A) is permitted for every application without hesitation - the "carefree package".

ROOFINOX began developing a highly flexible stainless steel over 30 years ago. The result is HFX stainless that is noticeably more flexible and glare-free while retaining the proven advantages of stainless steel (rustproof, stronger, more durable).

Patinating stainless steel - only on the roof, please!

At the same time as patinating stainless steel, the portable Walkman was invented in the late 1970s. Over the years, it turned out that this once advanced technology was overtaken - first by portable CD players, then iPods and now streaming on mobile phones.

What is patinating stainless steel?

The development of patinated stainless steel began in the 1970s because an alternative to the problematic roofing materials lead and zinc was needed. A grey and matte appearance could be achieved with tin-plated stainless steel, because at that time stainless steel was only available in a shiny finish and was therefore unsuitable for roofing in this form.

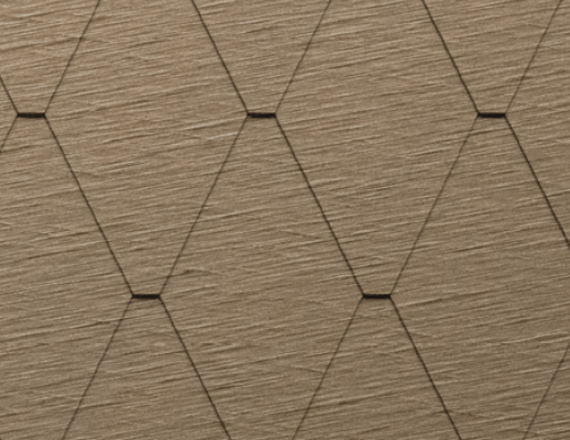

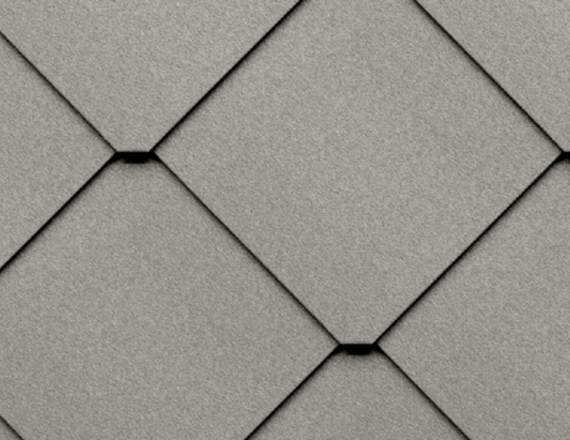

Patinated stainless steel is low-alloy chromium steel that has been electrolytically coated with tin and darkens over time due to the effects of weathering. It loses its shine and develops a grey patina - however, undesirable discolouration often occurs or the patina develops unevenly.

Lead is now considered obsolete, which is why patinating stainless steel is still used in the renovation of historic buildings or to match the cityscape, such as in Vienna, a city with a long tradition of grey metals - but only in the roof area.

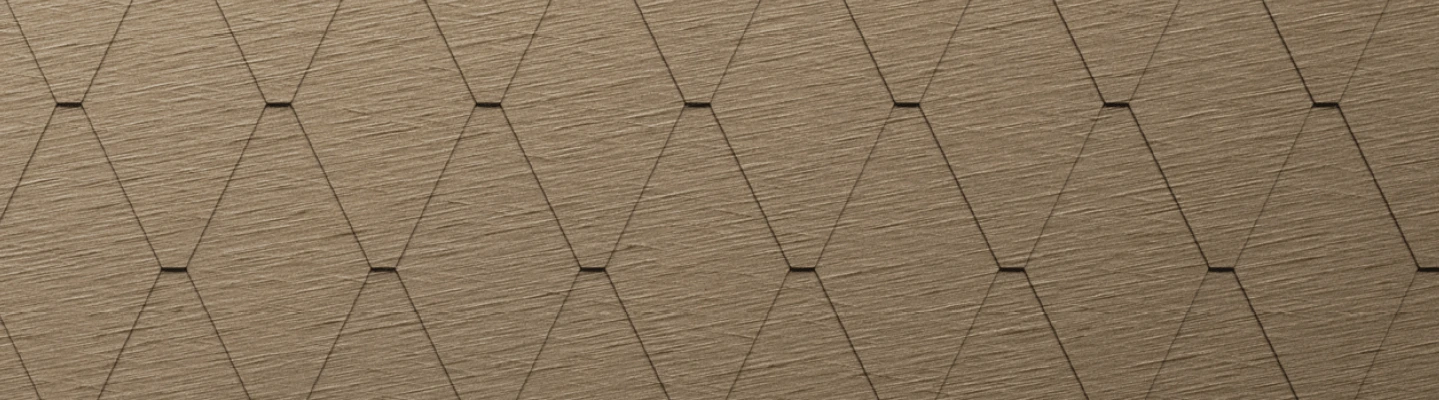

The following object shows the use of stainless steel with patina in combination with naturally ageing wood. The patination works quite well here because the material was only used on the roof, the entire object is evenly weathered and there were no disruptive environmental influences:

Why is patinating stainless steel only permitted on the roof?

Numerous problems with patinating stainless steel and a very limited field of application led to the development of HFX stainless over 30 years ago. The carefree HFX stainless is suitable for all building envelope applications and impresses with its uncomplicated use. The most common disadvantages of tin-plated stainless steel are:

Uneven patina

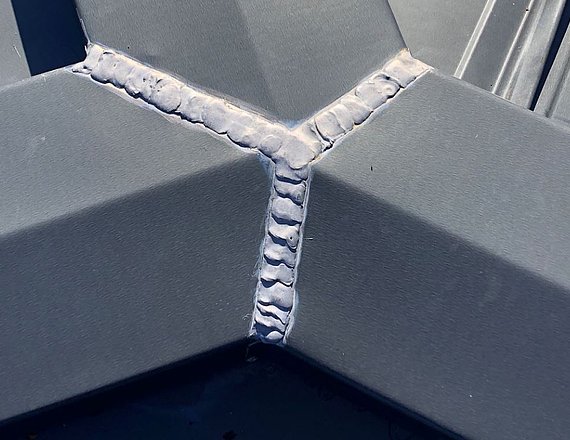

Fingerprints and other processing residues can occur during processing. In addition, protruding components such as canopies, window sills or roof overhangs lead to staining and an uneven surface. In addition, the reaction with environmental influences leads to discolouration, which cannot be cleaned or removed due to the wafer-thin patina layer.

Flawless work desired

In most cases, a flawless end result is desired, but owners are rarely familiar with the special features of patinating surfaces. Fingerprints, traces of processing and discolouration or patination phases of varying duration in particular cause uncertainty and unwanted complaints

Less resistant to corrosion

Low-alloy stainless steel is used for tinning; this and the wafer-thin tin layer are significantly less corrosion-resistant than HFX stainless. This can lead to numerous problems and discolouration when patinating stainless steel is combined with other materials - such as wood, bitumen, roof tiles or copper.

Missing complete system - only roof, no facade

The limited area of application only allows roof surfaces, edgings or roof drainage to be made from patinated stainless steel. For all other areas of the building envelope, patinated stainless steel is not recommended by any manufacturer for the reasons mentioned above. This means no edging for terraces and balconies, no window sills or panels and, of course, no facades.

Why is brush-rolled HFX stainless the most advanced stainless steel?

Brush-rolled HFX stainless is 4 times more matte than ordinary stainless steel, easier to work with and comes in a matte and elegant grey; without any delicate patina and without any restrictions or worries! Available as a complete system, HFX stainless is more sustainable, more durable, more beautiful and suitable for any location without changing its appearance.

Incorrect applications or unacceptable locations are a thing of the past with HFX stainless. Avoidable complaints, unsightly discolouration or lack of cleaning options for patinated stainless steel are a thing of the past.

Find out in a personal meeting what you should pay attention to when deciding on materials. This will help you to avoid undesirable results and complaints.

To experience the quality of our products and surfaces, we will be happy to send you a sample folder with original sample sheets.

From Austria - the better alternative

ROOFINOX is the Austrian manufacturer of the only complete stainless steel system for roofs and facades. Like no other.

The following 9 properties show some of the differences between HFX stainless, conventional stainless steel and other construction metals. At the same time, these properties are the main reasons why HFX stainless is perceived as a better alternative.