Why HFX stainless for roofs, facades and gutters do NOT shine?

How does ROOFINOX produce the mattest stainless steel surfaces?

Why should roofs and facades usually be matte?

Do you prefer details from a single source or a "lively" variety?

Gloss and glare regularly lead to conflicts and impairments, mostly because reflective materials are used unintentionally. In extreme cases, this has led to melted plastic furniture, car parts and door mats or singed hair on pool guests. In other cases, buildings have to be temporarily covered with facade nets for seasonal reasons so as not to obstruct traffic.

ROOFINOX began developing a particularly matte stainless steel over 30 years ago.

The result is HFX stainless, which is 4 times more matte and glare-free while retaining the proven advantages of stainless steel (rust-free, stronger & more durable).

Why use standardised matte surfaces for the roof and facade?

In a few words: to avoid the adverse effects of glare. These three examples show that impairment can go beyond annoying or unpleasant glare or disputes with neighbours:

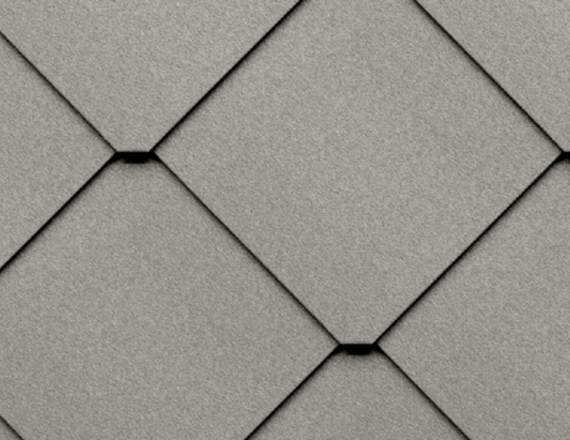

Matte is not the same as matte - direct comparison of "matte" surfaces.

Numerous surfaces are advertised as matte surfaces, but a direct comparison reveals clear differences in gloss behaviour. An example from our consulting practice with building owners and architects is shown in the following sample structure. Five matte surfaces were to be sampled in order to be able to compare the gloss behaviour directly on the building structure.

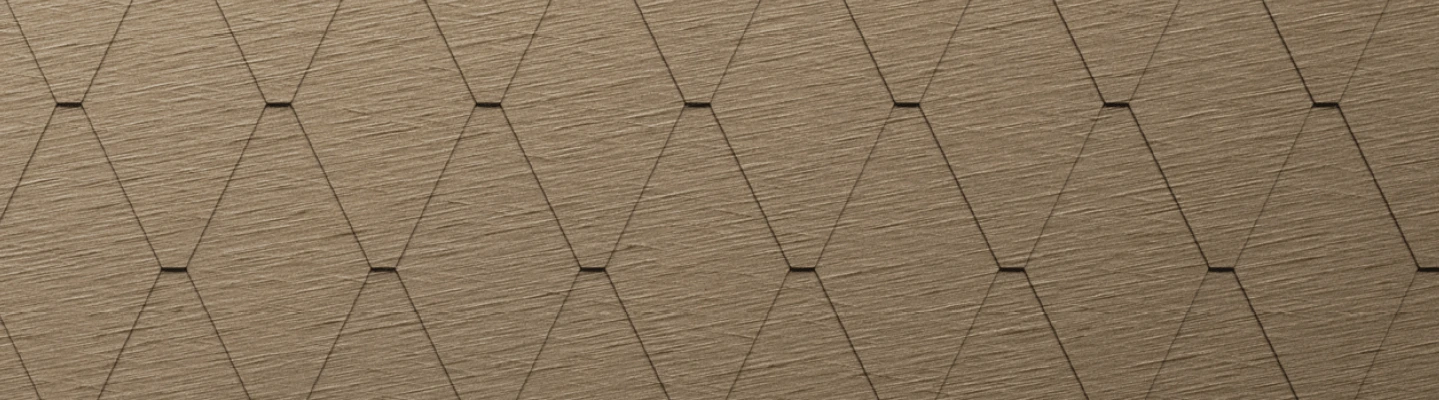

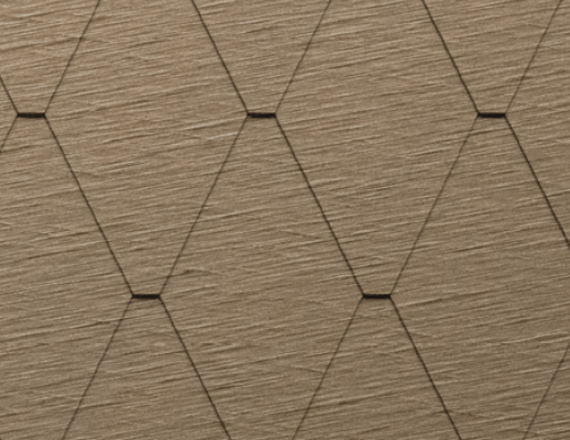

Five different surfaces were tested, three rows of samples per surface. The top three samples were conventional, matte stainless steel. The two lower rows were HFX stainless (CLASSIC and PEARL). While from one viewing angle all the surfaces provided a reasonably acceptable matte finish, changing the viewing angle revealed that the three commercially available surfaces were completely unsuitable because they were too shiny and even dazzling.

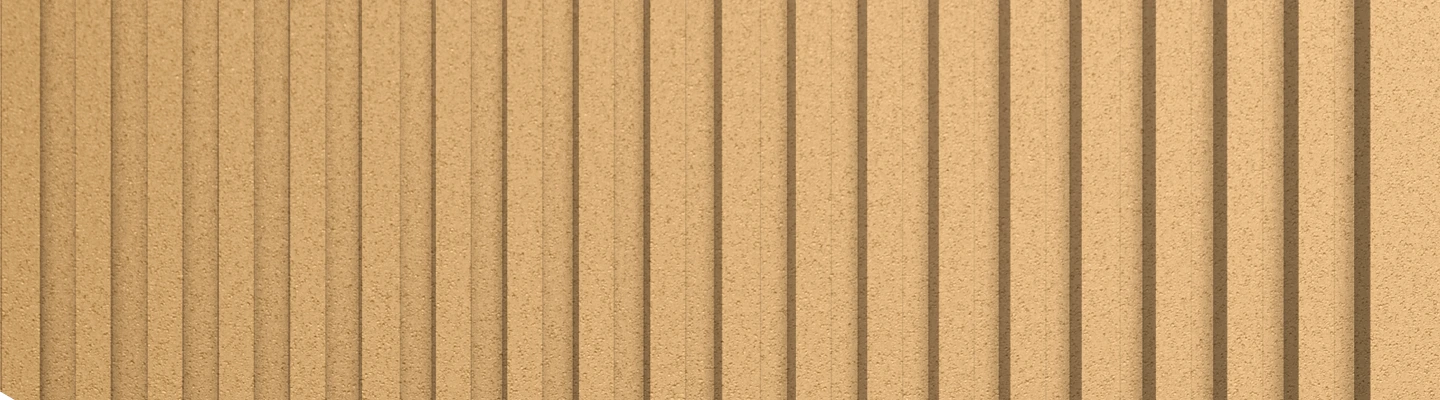

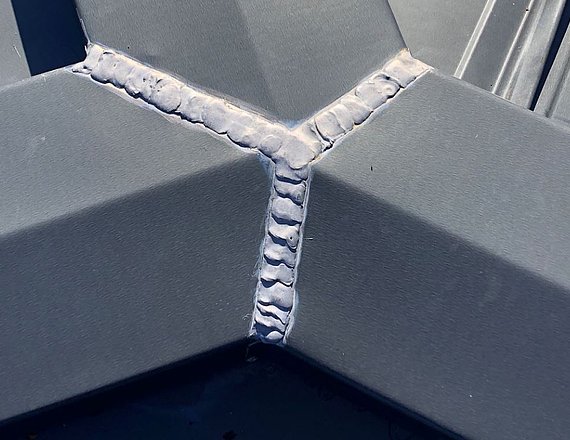

Standardised matte finish for the entire range, right down to the gutter brackets and downspout brackets.

ROOFINOX is the only manufacturer of a complete stainless steel system. This includes roof and facade products with a comprehensive range of accessories and, in particular, roof drainage and cladding from a single source. Over 4000 different items enable building projects with a consistent aesthetic! Therefore, when it comes to roof drainage, make sure you choose a coordinated complete system where not only the fit is right, but above all a uniform matte surface is guaranteed!

Often, attention is not paid to consistency in the details and different materials, surfaces and, above all, gloss levels are mixed. This not only looks unattractive, in the worst case it can lead to corrosion and therefore premature replacement. With the complete roof drainage system from ROOFINOX, everything comes from a single source with a uniform surface, even the supposedly barely visible gutter brackets and downspout brackets.

The standardised matte surface for the entire roof drainage system, including downspout bracktes and gutter brackets, does not incur any additional costs!

What makes ROOFINOX surfaces so matte?

In the course of developing HFX stainless over 30 years ago, we worked intensively on how to make our surfaces incomparably matte. We focussed on the following parameters:

Diffuse reflection

The roughness of the surface causes diffuse reflection of light; this is in contrast to the specular or mirror reflection caused by smooth surfaces. As a rule of thumb, the rougher a surface, the more matte it is.

The illustrations below show a roughness diagram, simply put a cross-section through the surface.

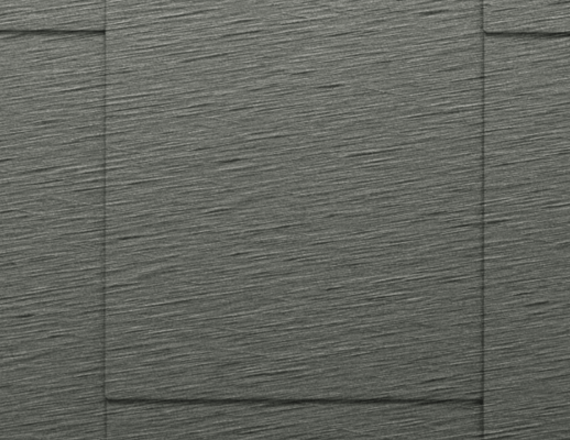

Texture

However, the average roughness is not sufficient to produce ultra-matte surfaces. A surface only becomes really matte when the shape and arrangement of the depressions and elevations are also adjusted.

The following illustrations show microscope images at 20x magnification.

Comparison of HFX stainless with ordinary stainless steel surfaces

The following picture shows different stainless steel surfaces advertised as matte. It is immediately clear that not all matte finishes are the same.

The clearly visible difference can also be technically verified by measuring the gloss levels of these surfaces at 20° and 60° using a reflectometer or gloss meter. The following table shows the measured values for the surfaces shown above from left to right:

| Surface | Gloss level in per cent at measuring angle 20° | Gloss level in per cent at measuring angle 60° |

| HFX stainless brush-rolled | 0,35 | 3,15 |

| HFX stainless bead-blasted | 0,35 | 3,93 |

| Pattern-rolled stainless steel | 0,75 | 4,15 |

| ordinary stainless steel | 1,05 | 6,50 |

| mill-finished stainless steel | 0,50 | 5,00 |

Glossy or matte?

Of course, this question is also purely a matter of taste. One thing is certain, however: mixing matte and glossy surfaces only works if it is done skilfully and deliberately, not by accident. We have observed a clear majority in favour of matte surfaces for roofs and facades, with a few prominent exceptions confirming this experience.

High-gloss surfaces are particularly popular for interiors or for eye-catching details where the mirror effect shapes the building, courtyard or room and creates a dialogue with the surroundings.

There are many terms and complexities in connection with stainless steel,

so there can be a lot to discuss.

Find out in a personal meeting what you should pay attention to when deciding on materials. This will help you to avoid undesirable results and complaints.

To experience the quality of our products and surfaces, we will be happy to send you a sample folder with original sample sheets.

From Austria - the better alternative

ROOFINOX is the Austrian manufacturer of the only complete stainless steel system for roofs and facades. Like no other.

The following 9 properties show some of the differences between HFX stainless, conventional stainless steel and other construction metals. At the same time, these properties are the main reasons why HFX stainless is perceived as a better alternative.