For all those who prefer gluing to soldering!

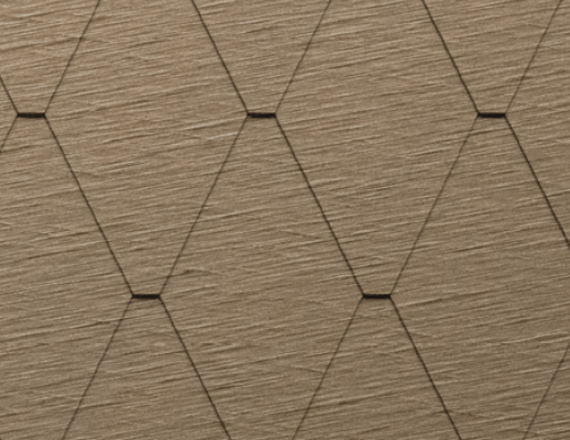

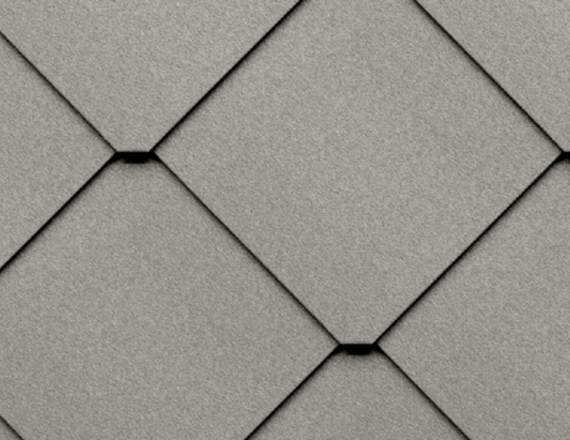

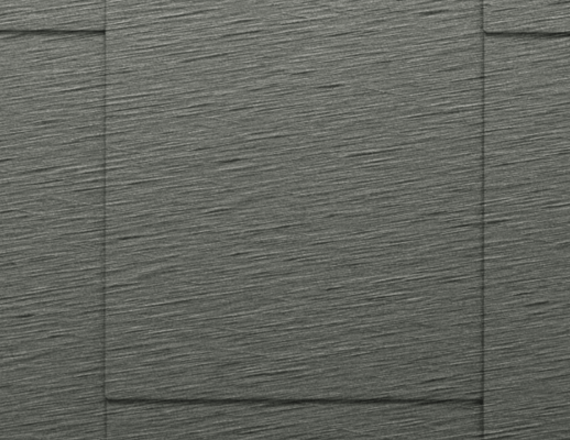

When stainless steel is used in many constructions, it is necessary to join different components together. When using stainless steel in the building envelope, for example on the roof, on the façade, in the roof drainage or in the sheet metal, it is not only important that these connections are stable. No, they must also look aesthetically pleasing and, above all, be watertight to protect the building from water ingress.

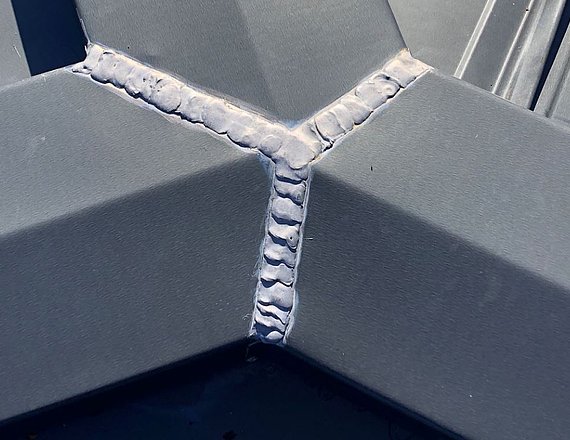

There are various ways to make the joints of stainless steel components stable and tight. The best known and recommended method for ROOFINOX HFX stainless is soldering, which works perfectly with ROOFINOX FLM flux and lasts for an eternity.

Nevertheless, poor soldering results are not uncommon. Soldering requires a certain amount of preparation, the right material, tools and skill, which is why many craftsmen find it a difficult job.

Bonding ROOFINOX HFX stainless is a welcome alternative.

Adhesive joints have become established in recent years, particularly in the area of roof drainage, for example when connecting guttering, and the use of adhesive joints is also increasing for rear-ventilated curtain walls in order to avoid unsightly soldered seams or rivets.

In order to guarantee the safe use of ROOFINOX HFX stainless bonding, ROOFINOX has carried out various bonding and adhesion tests with an established adhesive manufacturer. These tests were carried out on all our surfaces without a primer.

All tests have confirmed that ROOFINOX HFX stainless can be permanently bonded. However, the material should be cleaned and degreased before bonding. However, a primer does not need to be used. ROOFINOX also points out that the adhesive manufacturer's specifications and guidelines must always be observed. For further information, you can always contact us and request the test certificate.